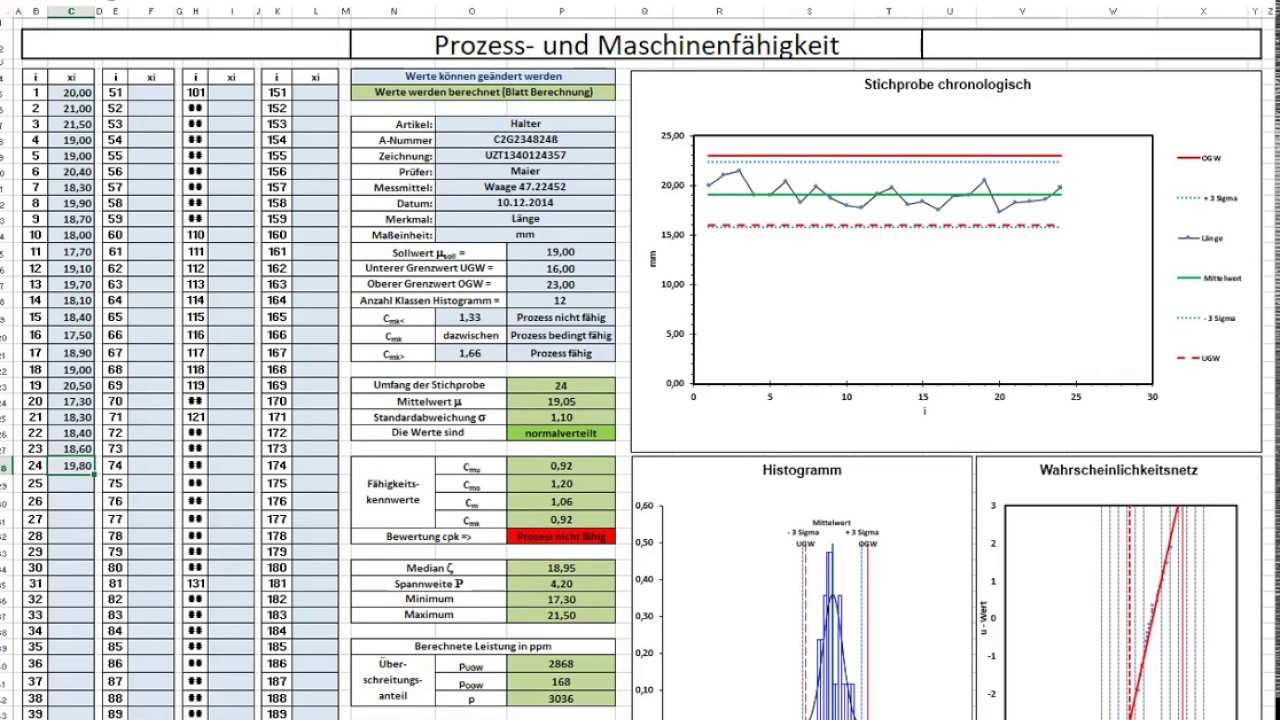

Generally you use this when a process is too new to determine if it is under statistical control. Pp and PPk are used for Process Performance. Process capability uses the process sigma value determined from either the Moving Range, Range or Sigma control charts. This often happens with a mature process that has been around for a while. Generally you use this when a process is under statistical control. In both cases we want to try to verify if the process can meet to meet Customer CTQs requirements.Ĭp, and Cpk are used for Process Capability. Pp and Ppk are called Process Performance. Cp and Cpk are called Process Capability. Huawei y5 2017 mya l22 frp lock remove google accountĪgain, this will help me make the article better for you and everyone else. This will help me make the article even better for you. If you are not finding what you are looking for, please let me know in the notes below. There are also crib notes on what the equations mean in a real performance sense, what you should be able to tell about a process depending on Cp and Cpk values and more. In other words, it allows us to compare apple processes to orange processes! This is a long article, but I thought it was important to keep Cp and Cpk together. In Six Sigma we want to describe processes quality in terms of sigma because this gives us an easy way to talk about how capable different processes are using a common mathematical framework. Calculators and Converters.Cp and Cpk are considered short-term potential capability measures for a process. Related Calculator: Cp and Cpk Calculator.

Generally, the final solution of the process capability is specified either in the form of calculations or histograms Process Capability Index Cpk Definition: Process capability index cpk is the measure of process capability. What is the process capability of the process? Cp and Cpk are used in Six Sigma Quality Methods for analyzing the performance of the process carried out to deliver any product. It shows how closely a process is able to produce the output to its overall specifications. Process capability index cpk is the measure of process capability. Generally, the final solution of the process capability is specified either in the form of calculations or histograms.

Process capability is a technique to find out the measurable property of a process to a specification.

#CP AND CPK CALCULATIONS IN EXCEL HOW TO#

You can learn how to calculate Cp and Cpk values using this tutorial. The higher the sigma level, the better the process is performing. Both are used for the measure of a potential capability of a process in short term. Cp stands for process capability and Cpk stands for process capability index.

0 kommentar(er)

0 kommentar(er)